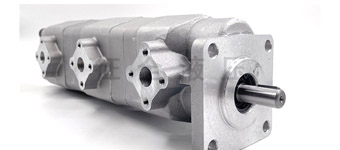

As a kind of fluid conveying equipment, gear pumps are widely used in different industrial fields. According to its application scenarios and requirements, gear pumps can be divided into high-pressure gear pumps and ordinary gear pumps. This article will deeply explore the differences between these two types of pumps, and compare them in terms of structure, working principle, and application fields.

structural difference

High-pressure gear pump: The structure of high-pressure gear pumps is usually optimized to meet higher pressure requirements. They may use stronger materials for gears and pump bodies to enhance their pressure-bearing capabilities. In addition, the high-pressure gear pump may also adopt a tighter sealing design to reduce leakage and ensure stable operation under high pressure.

Ordinary gear pump: The structure of ordinary gear pump is relatively simple, which is suitable for general fluid delivery needs. Its components may not be too heavy, and the seal design may be relatively simple. These pumps are generally suitable for low to moderate pressure conditions.

Differences in working principle

High-pressure gear pump: The working principle of high-pressure gear pump is similar to that of ordinary gear pump, that is, the volume of the working chamber is changed by the rotation of the gear, so as to realize the suction and discharge of liquid. However, high pressure gear pumps require more attention to ensure that no leaks and damage occur at high pressure.

Ordinary gear pump: The working principle of ordinary gear pump is relatively simple, and it is suitable for general liquid transportation. The volume change of its working chamber may not be as tight as that of a high-pressure gear pump, so its use under high-pressure conditions may be limited.

Differences in application fields

High-pressure gear pumps: High-pressure gear pumps are suitable for scenarios where high-viscosity, high-pressure liquids need to be transported. They are usually used in industrial fields, such as chemical industry, petroleum, energy, etc., to deal with media that require greater pressure.

Ordinary gear pumps: Ordinary gear pumps are suitable for some general liquid delivery scenarios, such as lubricating oil, clean water, coolant, etc. They have reliable performance in some low dropout conditions, but may not be up to the task of high pressure requirements.

Technical difficulty and cost difference

High-pressure gear pumps: High-pressure gear pumps may require more technical input and cost in terms of design, manufacture and maintenance. The use of stronger materials, tighter sealing systems, and more precise processing requirements may increase manufacturing costs and technical difficulties.

Ordinary gear pump: Ordinary gear pumps are usually relatively simple in terms of technical difficulty and cost. Its structure and design are relatively standardized, which can reduce manufacturing and maintenance costs to a certain extent.

To sum up, there are significant differences between high-pressure gear pumps and ordinary gear pumps in terms of structure, working principle, application fields and technical difficulty. According to actual needs, selecting the appropriate pump type is of great significance to ensure the normal operation of the system and prolong the life of the equipment.

中文

中文 English

English